HYPERLOOP- Next mode of Transportation successfully tested and How it works??

We have been hearing about HYPERLOOP for about last few years as the future mode of transportation. Now Virgin Hyperloop, California based Futuristic transport company successfully completed first passenger trail run in Nevada. This became a huge boost for the fifth mode of transportation.

In this article you can read about Hyperloop Transport system, its components and how it works.

Hyperloop is a new mode of transport that seeks to change this paradigm by being both fast and inexpensive for people and goods. Hyperloop consists of low pressure tubes with capsules that are transported at both low and high speeds through the length of the tube. The capsules are accelerated via magnetic linear accelerator fixed at various stations on the low pressure tube with rotors contained in each capsule. Passenger may enter and exit at the capsules on stations located either at the ends of the tube, or branches along the tube length.

One of the important feature of the capsule is its onboard compressor(around 400-450 hp), which serves two purposes.

TUBE

ROUTE

The Route of the hyperloop has been devised to satisfy the design requirement. it should be based on several considerations, including:-

These are the major components and some details about the future mode of transportation. And this article is based on my knowledge and references from Journals and articles related to it.

Share your thoughts and join the conversation. KEEP READING.

Hyperloop consist of several distinct components. Major components are:-

- Capsule

- Tube

- Propulsion

- Route

Capsule are sealed structures carrying passengers and vehicles. It can carry up to 28 passengers each that travel along the interior of the tube on average every 2 minutes. Larger capsules are also been sized that allows the transport of vehicles along with passengers. The capsules are supported via bearing that operates using a compressed air reservoir and aerodynamic lift.

To travel at high speeds, the greatest power requirement is normally to overcome air resistance. Aerodynamic drag increases with the cube of speed and thus power requirement increases with the cube of speed. So as to reduce the drag effect, capsule is moving inside a low pressure tunnel.

The capsule travels at 760 mph and in order to optimise the capsule speed and performance, the frontal area has been minimised for size while maintaining passenger comfort. The vehicle is streamlined to reduce drag and features a compressor at the leading face to ingest incoming air for levitation and to laser extend propulsion. Main features of the capsule are follows:-

- Tube air is compressed with a compression ratio of 20:1 via axial compressor.

- Upto 60% of this air is bypassed.

- Some of the air is cooled and compressed for passenger version with additional cooling afterwards.

- Onboard water tank is used for cooling of the air.

Interior of the capsule is specifically designed with passenger safety and comfort in mind. Capsule weighs around 5500lb including seats, restraint systems, interior and door panels, luggage compartment etc.

One of the important feature of the capsule is its onboard compressor(around 400-450 hp), which serves two purposes.

- Allows the capsule to traverse the relativity narrow tube without choking flow that travels between capsule and tube walls by compressing air that is bypassed through the capsule.

- Supplies air to air bearings that support the weight of the capsule throughout the journey.

Suspension of the capsule within the tube presents a substantial technical challenge due to transonic cruising velocities. A viable technical solution is magnetic levitation. However the cost associated with this is high. So an alternative to this is air bearing suspension. It offers stability and extremely low drag at a feasible cost. Extremely pressurized and aerodynamic air bearings are well suited for the hyperloop due to exceptionally high stiffness, which is required to maintain stability at high speeds.

TUBE

Hyperloop consist of partially evacuated cylindrical tube that connects the different locations in a closed loop system. The tube is specifically sized for optimal air flow around the capsule improving performance and energy consumption at expected travel speed.

In order to minimise the cost of the tube, it will be elevated on pillars which reduce the footprint required on the ground and the size of the construction area required. The geometry of the tube depends on either the passenger version or passenger plus vehicle version. Approx diameter of the tube is to be 7ft 4 in. Tube thickness is between 0.8 and 0.9 inch. This tube will be supported by pillars which constrain the tube in vertical direction but allow longitudinal slip for thermal expansion as well as dampened lateral slip to reduce the risk possessed by earthquakes.

PROPULSION

|

| Tube structure of hyperloop |

PROPULSION

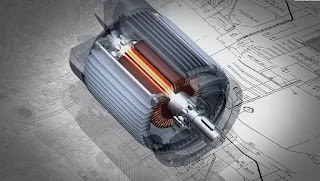

Propulsion of this system is a linear motor, which is developed to accelerate the capsule above 760 mph at a max of 1g per comfort. The moving motor element will be located on the vehicle for weight savings and power requirement while the tube will incorporate the stationary motor element which powers the vehicle.This whole project is to consume an average of 21 MW. This includes the power needed to makeup for propulsion motor efficiency, aerodynamic drag, charging the batteries to power on board compressor etc. A solar array covering the entire hyperloop is large enough to provide an annual average of 57 MW power.

Since the peak power of accelerating and decelerating capsules are up to 3 times the average power. The power architecture includes a battery array at each accelerator, allowing the solar array to provide only the average power needed to run the system. Power from the grid is needed only when solar power is not available.

In the linear motor, the rotor is connected to the capsule and stator is connected to tube. Rotor is an aluminium blade and current flows mainly in outer part of this blade, allowing it to be hollow to decrease weight and cost. As stator is connected to the bottom of the tube, it takes to accelerate and decelerate between 300 and 760 mph. Laid out symmetrically on each side of the rotor, its electrical configuration is 3 phase, 1 slot per pole per phase, with a variable linear pitch. The number of turns per slot also varies along the length of the stator, allowing the inverter to operate at nearly constant voltage, which simplifies the power electronics design.

Energy storage component of the hyperloop uses lithium ion cells, which is economical. By using Li ion cells, degradation due to cycling is not an issue because launching 1 capsule only uses 0.5% of the total energy.With proper construction and controls, the battery could be directly connected to the HVDC bus, eliminating the need for an additional DC/DC converter to connect into the propulsion system.

The Route of the hyperloop has been devised to satisfy the design requirement. it should be based on several considerations, including:-

- Maintaining the tube as closely as possible to existing rights of way.

- Limiting the maximum capsule speed to 760 mph.

- Limiting acceleration on passengers to 0.5g.

- Optimising locations of the linear motor tube sections driving the capsules.

- Local geographical constrains including location of urban areas, mountain ranges, reservoirs, national parks, roads, airport etc.

The tube bend radii is calculated so that the passenger does not experience inertial accelerations that exceed 0.5g. This is deemed the maximum inertial acceleration that can be comfortably sustained by humans. In order to do this, the route should be optimised. This can be achieved by deviating from the current highway system, earth removal and constructing pylons to achieve elevation change or tunnelling.

These are the major components and some details about the future mode of transportation. And this article is based on my knowledge and references from Journals and articles related to it.

Share your thoughts and join the conversation. KEEP READING.

Keep going..quiet informative...and easy to understand

ReplyDeleteThank you. Keep reading.

ReplyDeleteMostly I do not comment on any post, but your blog has lots of knowledge. it's forcing me to do this. it has really amazing content please share more information with us.Magnet manufacturer

ReplyDeleteThank you for the valuable feedback. Keep reading and support us.

Delete