BY AFZAL YOUSAF

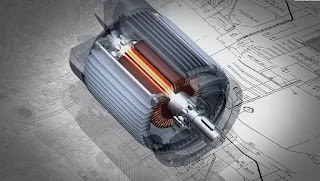

Brushless DC Motor (BLDC) is widely used in Electric vehicles like E-bikes, E-rickshaws, small electric loading vehicles etc and is more popular among EV enthusiasts and designers. BLDC is a successor of brushed DC Motor and it uses Hall sensors instead of brushes to control the drive signals. Brushless motors have improved efficiency and reliability than brushed ones. Also it produce large amount of torque and a wide speed range.

But some BLDC Motors do not have sensors. They are called Sensorless BLDC Motors.

In this article, you can read about the technology and working of Sensorless BLDC Motors.

In Sensorless BLDC Motor, Instead of using Hall effect sensors to determine position or speed of rotor, we are using the phenomena of Back EMF. This sensorless BLDC Motor is also called sensorless trapezoidal controlled BLDC as voltage waveforms of these have a trapezoidal shape. In this sensorless technology, Back EMF is used to determine the position of rotor with respect to stator.

|

Sensorless BLDC Control using Back EMF

Photo Credit:- All About Circuits |

WorkingWhen input voltage is applied to motor, the winding gets excited and rotor starts to rotate. The motor somewhat behaves like a generator when its rotor cuts the generated magnetic field and rotates. As are result, apart from receiving voltage, motor generates its own voltage and this voltage is referred as Back EMF (back electromotive force).

This generated Back EMF is used to determine the position and speed of the rotor to control the motor and hence no sensors (ie; Hall sensors) required. As this controlling is not easy, in most sensorless BLDC Motor, a microcontroller, Digital signal processor or a Driver IC is used to control the whole process.

Some sensorless BLDC have integrated power MOSFETs For providing continuous current. But it requires some external components and not all sensorless BLDC's uses that.

Disadvantages

There are some disadvantage for this sensorless technology which are listed below:-

- When rotor of sensorless BLDC is rotating, this technology work fine. But when rotor is stationary, no Back EMF is generated and the drive circuit lacks the information to properly control the motor.

- Due to the relationship between Back emf and Angular speed, in low speed, less Back EMF is generated.

To Overcome the disadvantage of no Back emf while rotor is not rotating, techniques like Initial position detect and Align and go technique is used.

Initial position detect - Determining the position of rotor based on the deterministic inductance variation in BLDC Motor.

Align and go technique - Application of voltage to one of the phases to force the motor into a known alignment.

Even though it has some disadvantages, due to technical advancement, this sensorless BLDC Technology will be used in electric vehicles applications. Sensorless system reduces the cost and require few interconnection between the motor and the drive circuit. And in low speed applications, sensor based BLDC is still preferred.

This article is based on my knowledge and reference on technical online magazines.

Share your thoughts and join the conversation. Keep Reading.

Comments

Post a Comment

Please do not enter any spam link in the comment box.